All about Box printers are a particular type of machine that is used to design and print on boxes. These box printers help in converting the graphics or text onto your boxes. The box printer plays a vital role in the printing and packaging industry. It makes the boxes highlighted and crafted. The box printer is crucial for effective branding and marketing of a product.

In other words, the box printer helps attract the customer’s attention, brand recognition, and sales enhancement. The box printer helps convey your brand message to the customer and makes your brand visible among others. So, what are the different box printing techniques that are popular and helpful for different types of boxes? Let’s explore it together.

Navigating The Printing Maze

Flexographic Printing

Flexography is a printing process that is exceptionally high speed roll-filled web printing. This type of printing is highly speedy and can print up to 2000 linear feet per minute. This type of printing is mainly used for high end printing labels and other flexible box packaging. This printing is known for its affordability, durability, and simple and elegant design. The box printer can print high quality prints on various materials like corrugated boards, paper boards, foil, kraft papers, films, etc.

Offset Printing

Offset printing or lithography is a printing process in which metal plates, rubber rollers, and printing mediums are included. During this process, the image is created on a metal plate. The metal plate transfers the image to a rubber blanket or rubber roller. The rubber roller rolls and presses down to print the image on the required material. Thus, the print medium is not directly in contact with the metal plate in this process. The lithography method is known for its durability, high speed, and affordability.

Moreover, this method is widely used for accurate color tones and high quality images. Graphic lithographic printers can be used to make complex designs. However, it is a little more expensive than flexography. This method is used for small orders.

Digital Printing

Another helpful printing process is digital printing. In this method, the digital images are directly printed on the required medium without any metal plate or rubber roller. This method is widely used to print brochures, files, folders, booklets, boxes, and educational materials. This method uses the CMYK color technique to help in getting the exact color tone. This method is perfect for short run orders. Digital printing offers fast turnaround time, reasonable rates, and elegant finishing. The only drawback of digital printers is that the printing quality is lower than that of offset and flexographic printing.

Ultraviolet Printing

Ultraviolet printing is one of the latest printing methods that use digital technology and ultraviolet rays to get the print on any surface. The ultraviolet rays help in the even distribution and instant drying of ink. Ultraviolet printing is known for its vibrant color, high class finishes, scratch resistant surface, fast drying process, and high quality premium look. However, UV printing is limited to a few materials and excludes all packaging materials.

Moreover, UV printers are expensive, and their prints are pricier than those of other methods.

Screen Printing

Screen printing is another widely used printing method for boxes. In this method, ink is spread over a required and selected stencil, and the design is created by meshing the screen and squeezing from machines. This method is widely used for printing on fabric and paper, but it can also be used for printing on wood, metal, glass, and plastic. Silk screen printing creates vibrant and tactile prints. They are suitable for making prints that need thick coatings. Silk printing is widely used in the packaging industry, but it is not recommended for bulk orders due to its low speed process.

Also Read: Gable Boxes- A Game Changing Packaging Boxes

Choosing The Right Method For Your Packaging Needs

Different printing methods are widely used in the packaging and printing industry. All about Box Printers have their specification and limitations. You can use the digital printing technique if you need a budget friendly option. It helps cut costs and is helpful for smaller budget holders for printing. If the budget is not a matter for you and you need high quality and more extensive volume printing, UV and offset printing are considered best.

In addition, flexo printing is used for large run orders, and digital printing is best for short run orders. However, if your design is complex and needs lots of detailing, offset or UV printing is the simple solution. If you need the fastest turnaround time, then digital printing works best in providing the order in minimum time. In comparison, flexo and UV take slightly longer to complete the task. If you need sustainable printing solutions, use water based inks and sustainable materials to show your responsible behavior towards nature.

Magic Of Printing In Brand Recognition And Growth

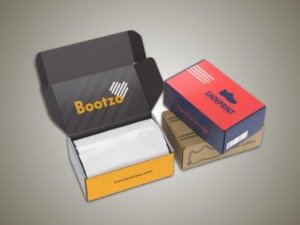

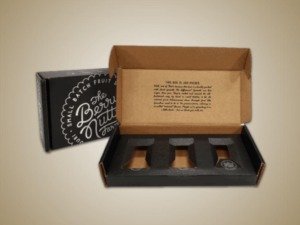

Printing is necessary for product packaging. It helps create an impact on the whole product outlook. Moreover, unique and innovative printing can make your product stand out among the competitors and give it an attractive and elegant look.

All about Box Printers, Printing is also mandatory for shipping boxes. The highlighted shipping boxes, printed with your brand name and logo, help in safe and secure transit and delivery to the required destination.

In addition, product packaging is helpful for marketing and recognizing your brand. So whether you want to promote your brand or launch your new products or services, If you wish to enhance your business setup, you need high end printing on your precious product. The right printing choice creates an everlasting impact on your sales and brand boost.